This article stems from real-life experience with a customer who was looking for a precise and customised solution to meet a variety of lighting needs in their phytotron. This case study highlights the importance of having a flexible, effective system specifically tuned to grow different types of plants at all stages of growth, ensuring optimal and efficient results.

When it comes to phytotrons, lighting is more than just a technical detail; it is the key factor that will determine the success of your crops. From tomatoes to lettuce to cuttings, each plant requires particular lighting conditions for healthy and productive growth.

What aspects should you consider to properly light your phytotron?

Accurate and Adequate Measurement:

- The most relevant parameter is PPFD (Photosynthetic Photon Flux Density), which measures how much useful light plants receive to efficiently photosynthesise.

- It is crucial to always measure from the exact location of the luminaires to the top surface of the plant canopy, as this distance directly influences the effective light intensity reaching the plants.

LED Light Type:

- Full spectrum LEDs are recommended because of their ability to cover all the needs of the plants throughout their entire vegetative cycle.

- Blue light is especially beneficial for encouraging the development of compact, vigorous and healthy leaves. In contrast, red light is essential for stimulating flowering and fruiting processes, thus maximising crop productivity.

Dimming and Light Control Systems:

- Having systems capable of adjusting light intensity is a must, especially when growing different types of plants with varying light requirements.

- Opt for systems that can easily operate at specific power levels, such as 25%, 50%, and 100%, allowing for quick and precise adaptation to different phases of plant growth.

Key Light Parameters by Crop Type

| Crop | Stage | Recommended PPFD |

| Lettuce | Seedling | 100-300 µmol/s/m² Lettuce |

| Lettuce | Vegetative Growth | 200-350 µmol/s/m² Tomato |

| Tomato | Seedling | 150-350 µmol/s/m² Tomato |

| Tomato | Vegetative Growth | 400-600 µmol/s/m² Tomato |

| Tomato | Flowering/fructification | 480-800 µmol/s/m² |

| Cuttings | Callus Development | 50-70 µmol/s/m² |

| Cuttings | Root development | 100-300 µmol/s/m² |

Case Study: Solution Realised for a Client

Case Study: Solution Realised for a Client

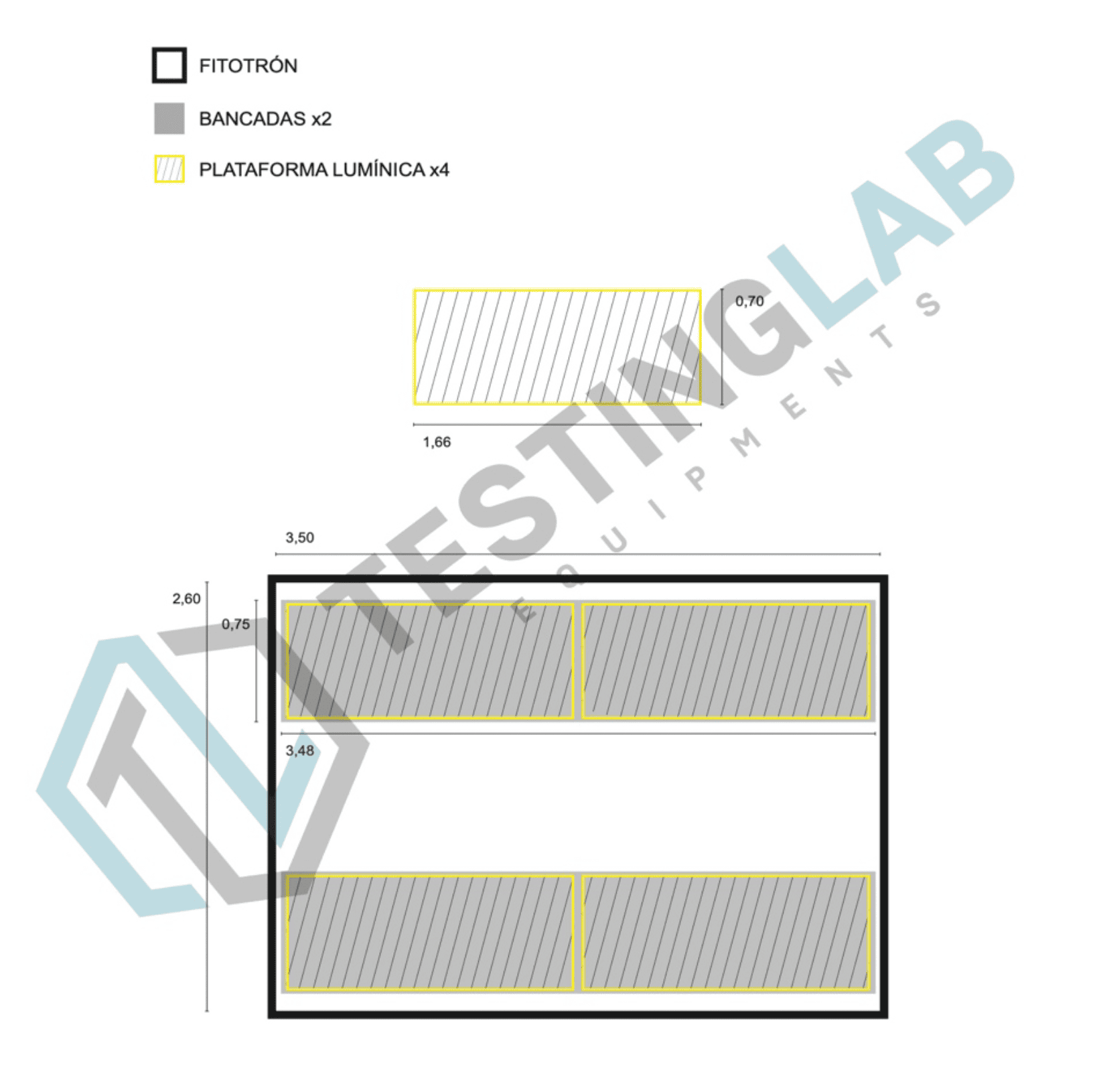

After multiple discussions and detailed analysis of the client’s specific needs, we finally developed a customised and highly effective technical and commercial proposal. The proposed solution comprehensively covered their requirements and allowed for an easy adaptation to their existing structures.

Final Proposed Solution:

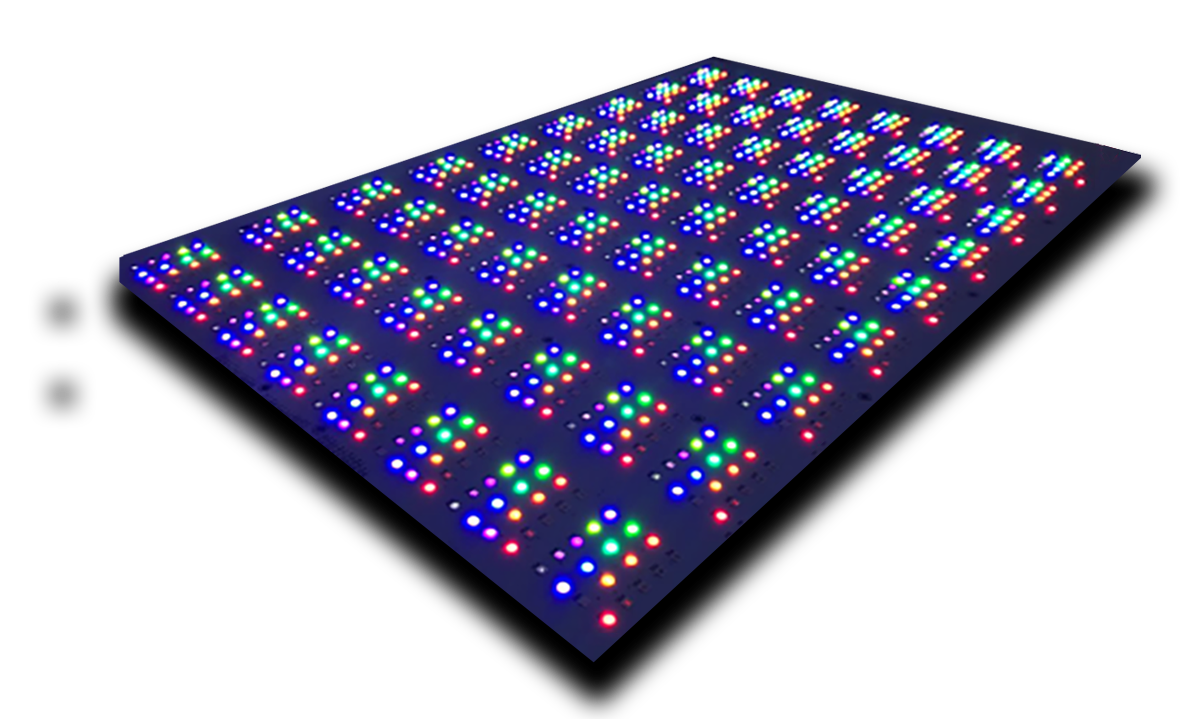

- Advanced LED lighting system with three independent channels (2700K, 4000K and 6000K), each individually dimmable from 0% to 100%.

- Capable of reaching a maximum luminous intensity of up to 500 µmol/m²/s at an effective distance of 300 mm, ensuring ideal conditions for various types of crops.

- Plug&Play solution specifically designed to adapt perfectly to the structure provided by the customer, guaranteeing ease and speed of installation.

This comprehensive proposal, the result of a thorough analysis of the customer’s specific needs, exemplifies the importance of providing highly adapted solutions. Our commitment is to ensure flexibility, energy efficiency and maximum operational efficiency, achieving exceptional and sustainable results in controlled cultivation within phytotrons.

Are you looking for the perfect light for your phytotron?

At TestingLab, we design customised LED lighting systems for every type of crop. Avoid mistakes in your trials and get reliable results from the very first cycle.